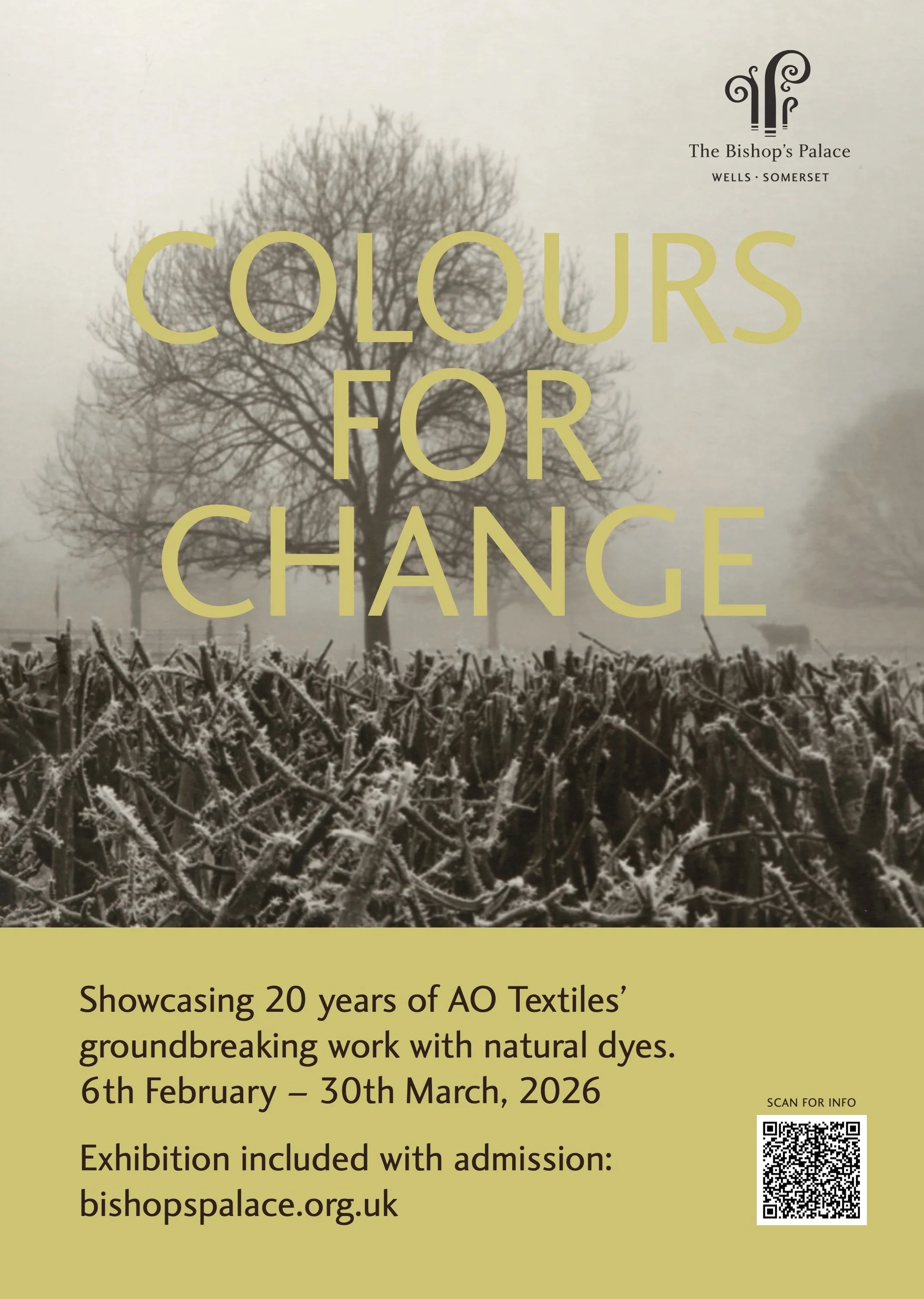

Colours for Change

Colours for Change

6th February to 30th March 2026

Everyone is warmly invited to our forthcoming exhibition at the breathtaking Bishop’s Palace, Wells, Somerset. Huge thank you to @bishopspalace for opening their extraordinary historic home to us.

This exhibition brings together highlights from our natural dye journey since 2006 from sustainable haute couture featured in Vogue and worn at the Oscars, to pioneering work transforming local agricultural tree waste into colour for industry here in Somerset.

The ancient trees in the Palace gardens have played a vital role in our colour, and design research, living collaborators that have informed our way forward.

Visit the exhibition to explore how fashion, textiles, natural dyes and climate innovation intersect in one remarkable place.

Colour palette

About our colours

Campeche

logwood dye is extracted from the heartwood of logwood trees(Haematoxylum or Haematoxylon campechianum)and originates from Central America. It is used to create a range of colours from violet, greys and blacks.

Rubea and Pale Rubea

We have chosen to add two colours, rubea and pale rubea to our palette that use madder as it is very versatile dye, producing multiple shades ranging from the most delicate pinks to a robust dark rich red. Madder dye is created from the roots of a madder plant.

Luteola

Weld is a dye plant that has been used for centuries to create a variety of vivid colours from bright yellow to both light and dark greens. This colour has been chosen as part of the ao textiles palette due to its flexibility and lightfastness. We have called it Luteola meaning yellow.

Castaneda

Our soft beige colour, is derived from chestnut extract sourced from the natural regrowth of chestnut wood in the Haut-Languedoc Regional Natural Park. We love the fact that this is so compatible with Emma’s practice based research into regenerative colour from trees.

Sustainability Commitment

All aspects of textile production; from the replacement of synthetic colour with natural dyes to sustainably sourced silk yarn, obtained through an environmentally friendly process that does not involve the use of pesticides and plays a key role in supporting rural communities. Certified by Oeko-tex Standard 100 certification. The ao textiles dyeing process received the stamp of approval from Greenpeace International’s Detox Fashion Campaign in 2013. Using 100% sustainably sourced Oeko-tex Standard 100, Class I-IV natural dyes, which are compliant with the requirements of the ZDHC Manufacturing Restricted Substances List V2.0. Additionally, mordants and dyes are GOTS certified. The exhaustion process employed in the dyehouse reduces wastewater and dye to negligible levels. Excess heat from steam pipes is channelled via a heat exchanger into the drying cupboard to dry yarn using no additional energy. Production has been reduced to almost zero waste as all fabric is made to order. Any yarn that is not woven is donated to recycling charities and to students. Gainsborough fabrics are designed with longevity in mind and often exceed their expected life span of 25 years.